Factory Intelligence. Made Simple.

Turn machine data into actionable insight - fast.

Your Factory.

Under Control

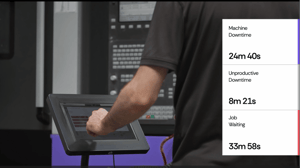

Get real-time data from machines and operators, anytime, anywhere. See what’s happening.

Spot inefficiencies. Act fast to improve performance.

Use real-time machine data to optimise schedules, tighten estimates, and deliver every job profitably—on time, every time.

Empower Your Team.

Accelerate Improvement.

FourJaw engages operators and surfaces actionable insights to help you eliminate bottlenecks, increase machine utilisation, and accelerate factory-wide improvement to support continuous improvement programmes.

Customer Testimonials

"FourJaw has delivered a significant and sustained improvement in the productivity levels we're getting from our manufacturing centres."

Monitoring downtime, eliminating the various causes of waste in our processes, and deploying colleagues to where they are needed most has helped achieve a 30 per cent overall increase in uptime.

“FourJaw is helping us move towards 4.0 based on our S&OP.”

Each month, it allows management to see our strengths and weaknesses and plan forward based on what we find. From a continuous improvement point of view, we now have concrete evidence of where to focus our energy, helping with costings, budgeting and machine utilisation.

“We’ve removed all back orders and are now in a position to deliver orders on time for customers worldwide.”

This is a tangible benefit of our unprecedented increase in machine productivity, and we’ve also improved staff retention with a calmer, less stressful working environment where operators have the autonomy to get on with the job.

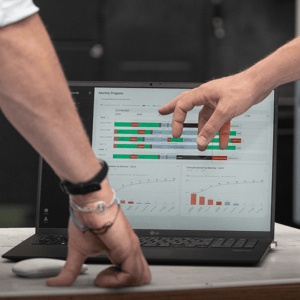

Get the insights your team needs to improve

Cut through the noise. Use custom dashboards to show the production data your operators, managers, and directors need to see, nothing more, nothing less.

-

Tailor views for specific shifts, cells, or roles in seconds.

-

Visualise performance instantly with simple drag-and-drop widgets.

-

Align your factory with a single, clear source of truth.

Platform Features

Everything you need to streamline and optimise processes to grow your business.

Gain capacity by improving processes and removing bottlenecks.

Simplify planning and communication for a more efficient factory floor.

Cut energy waste, streamline processes, and shrink your carbon footprint.

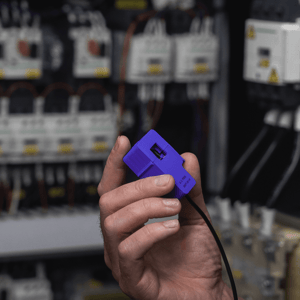

Install in Minutes

FourJaw works on ANY Machine, regardless of age or type.

Clip the sensors to the machine's power cables.

Connect the MachineLink IoT device to WiFi and mains power.

Use data insights to start identifying and removing inefficiencies.

Manufacturing Success Stories

Leading manufacturer of windows & doors improves productivity by 10%

From 19% to 47% - How this factory Transformed Machine Productivity

Fernco transforms factory insight and productivity

Aerospace Manufacturer, AVPE Systems increases factory uptime by 30%

Trusted by manufacturers worldwide

Download the FourJaw Brochure

See how FourJaw makes getting factory intelligence simple. Get the full breakdown of how it works, the results it delivers, and why it works for factories like yours.

Ready to

Learn More?

See how FourJaw's plug-and-play analytics can help you turn machine data into real productivity gains. What would you like to do next?

FourJaw FAQs

FourJaw provides plug-and-play manufacturing analytics that give you real-time visibility of machine performance, downtime, and productivity. Our production monitoring system enables manufacturers to identify bottlenecks, reduce unplanned downtime, and make data-driven decisions to improve efficiency and output across every machine, shift, and site.

FourJaw is used by manufacturers of all sizes and sectors, from aerospace and automotive to food & beverage, metals, and medical devices. Whether you run a small job shop or a global production facility, FourJaw helps your operations, engineering, continuous improvement, finance, and leadership teams make better decisions based on live, reliable production data.

We’re proud to support a diverse customer base:

- Over 50% are SME manufacturers

- 25% have global revenues exceeding £100 million

- More than 10% of these turnover £1 billion or more annually

Proactive customers typically see productivity gains of 10–30% within just a few months of installation. FourJaw helps you understand where time is lost, improve machine utilisation, balance workloads, cut energy waste, and drive continuous improvement initiatives such as Lean, Kaizen, and SMED, all backed by measurable ROI.